This post is the first installment of six regarding smart materials management in electronics industry.

This series aims to inform manufacturers of smart materials management’s structure in physical

and virtual perspective and how Neotel Technology help users transform from electronics materials

automation to self-governed materials management system.

Electronics industry is closer to a world of autonomous systems than ever before. Several years ago, it was just a distant goal for electronics manufacturing and SMT production line. Today, it's a reality that's beginning to shape the future of your factory.

If we look at the history of intralogistics is also a history of automation, from manual materials handling (reel type, particularly) to the lighting assisted system (Neo Light likes) to today’s fully automated storage and retrieval system (SMD BOX likes).

Today’s fevered interest in new technology, after a lull of several years, has plenty of precedent. Many trends are thrusting not only automation but also autonomous governance toward the top of the leading manufacture boss’ agenda, not least these three:

• A growing shortage of labor, becoming more critical during this pandemic period

• An explosion in demand from sophisticated supply chain management

• Some intriguing technical advances.

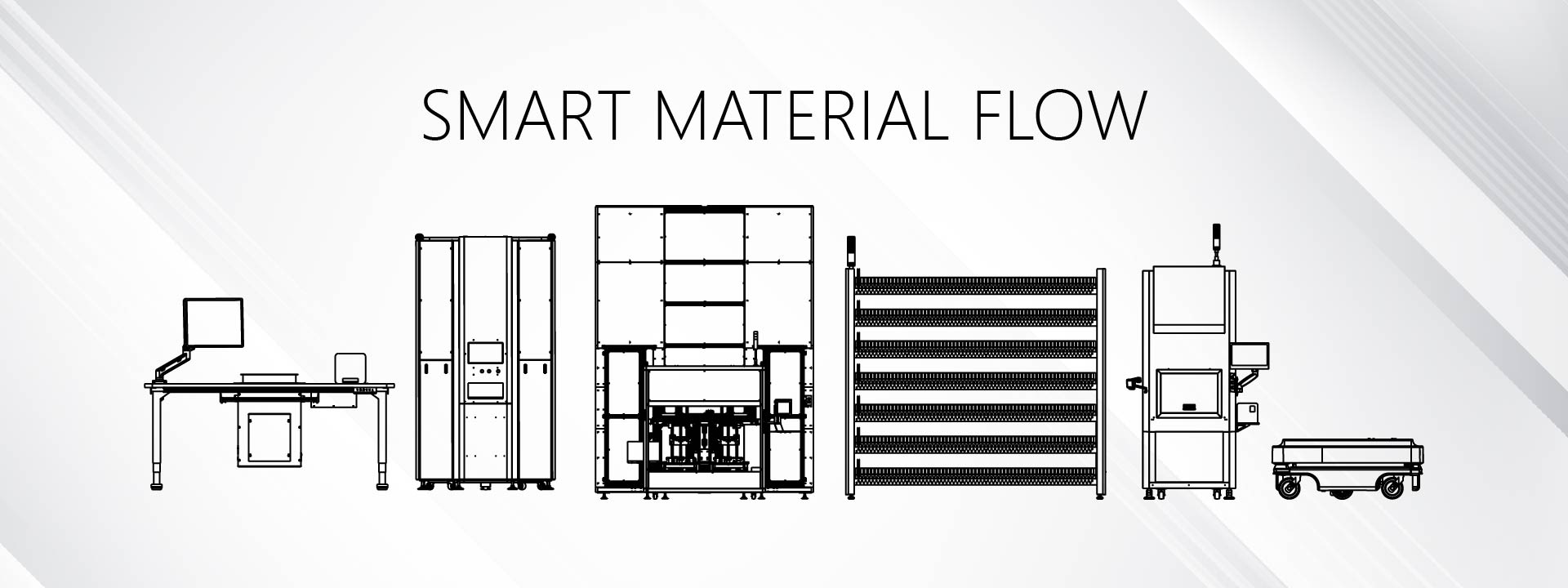

Thanks to advances in established technology in material handling sector such as pick to light (Neo Light) machine vision, Component counting (Neo Counter), automated storage technology( SMD BOX), artificial intelligence, wireless sensors, we are on a progressive path from automation toward autonomy. This is apparent by the notable progress in the areas of , light out factories, self-driving cars, autonomous drones and other applications.

Automation Vs. Autonomy

First, let's define the difference between automation and autonomy since there is confusion among these two terms. Autonomy is self-sufficient and requires no human intervention; it can learn and adjust to dynamic production environments and evolve as the environment around it changes.

Automation is narrowly focused on a specific task based on well-defined criteria and restricted to certain tasks it can perform. Within the electronics industry, for example, traditional automated storage system is the result of automation, where the system requires human intervention to control the material loading and unloading for specific task like kitting and replenishment.

Semi-autonomous: Multiple automated sequences a machine/system can perform without human input that result in a task being completed. We realized it is common semi-autonomous machine operation assumes that the operator performs some tasks. ie, Neo light system liberate operator from boring material search process however the whole process is admittedly relying on manual operation.

Semi-autonomous: Multiple automated sequences a machine/system can perform without human input that result in a task being completed. We realized it is common semi-autonomous machine operation assumes that the operator performs some tasks. ie, Neo light system liberate operator from boring material search process however the whole process is admittedly relying on manual operation.

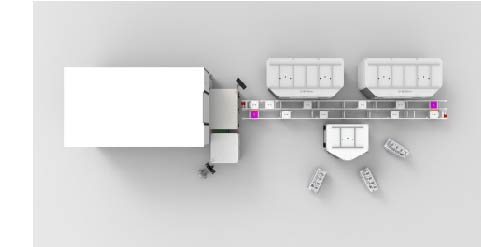

Autonomy is ability of a system to not only control a machinery but respond to unexpected scenario. The planning and control of intralogistics systems in line with versatile production systems of your factories requires new approaches and methods to cope with changing requirements within future factories. SMF software, Neotel Smart Material Flow software , will not follow a static, sequential approach as in conventional way since the materials planning (work instruction)are going to change in a high frequency.

Autonomy is ability of a system to not only control a machinery but respond to unexpected scenario. The planning and control of intralogistics systems in line with versatile production systems of your factories requires new approaches and methods to cope with changing requirements within future factories. SMF software, Neotel Smart Material Flow software , will not follow a static, sequential approach as in conventional way since the materials planning (work instruction)are going to change in a high frequency.