We have been pursuing ways to reduce people and increase efficiency. This is correct. From an economic point of view, we can understand that in a highly competitive market environment, the profits brought about by raising prices are short-term, and it cannot resist market changes. The transition period, but the profit from improving efficiency may well control cash flow and cost, and can bring long-term profit. From the perspective of the manufacturing industry, we can further understand how to design an organizational structure that achieves synergy between humans and machines.

Through the optimization and integration of resources, Neotel Technology fully provides innovative technologies, lean and efficient products in the fields of smart manufacturing, smart soldering, smart assembly, smart logistics, machine vision and big data, and provides comprehensive system-level solutions for industry users.

Neotel Technology's comprehensive materials solution better demonstrates that companies should rely on algorithms to identify data models and take corresponding actions independently, and people should focus on higher-level tasks, such as verifying algorithms, imagining new possibilities, and designing and Updated 'Human + Machine' organizational structure. It can be said that the interaction between humans and machines is truly achieved, so as to build an smart and self-adjusting factory, to adapt to a flexible and constantly developing business model, and to establish a new management model.

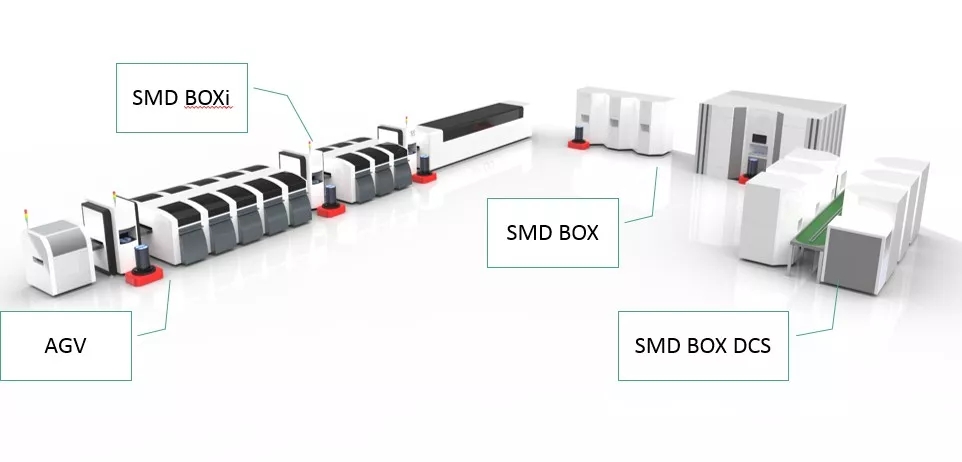

SMD BOX is not only a smart material management system in the traditional sense, it is also an extension of production equipment. The user management ability not only stays in the local inventory, it is closely integrated with advanced IoT Internet of Things technology and various production equipment to help Users store all information in the cloud without geographical and environmental restrictions. The innovatively designed WES warehouse material execution system uses a cloud computing architecture. Users only need a browser to implement a full range of equipment operations and material management: real-time inventory, MSD device management, temperature and humidity monitoring, BOM management, component files Management, MES communication, AGV path planning ...

Why do we need to implement an smart material execution system, this system is to allow warehouses, AGV trolleys, line side warehouses, mountor, workers, factory systems such as ERP, MES, SAP to achieve the goal of human-machine collaboration, reducing simplicity ,the manpower required for repetition and turnover, while liberating human resources, improving informatization and optimizing the material management model, is also the deployment of each link for the final era of the Internet of Things.